Precision in Motion

Power in Every Drive.

- High Reliability, Low Maintenance, and Maximum Efficiency

Experience and Expertise Build Our Strength

Manufacturing Experience

With 20 years of experience in the construction machinery parts industry, we have continuously accumulated production expertise and industry resources. We focus on providing cost-effective and reliable solutions to meet various application requirements.

Professional Technical Team

We have a professional technical team of 60 people covering design, process development, and production management. From standard products to non-standard customization, each project is handled by dedicated personnel with a focus on continuous product improvement.

Long-Term Partners

We have established long-term and stable partnerships with over 200 customers both domestically and internationally. With reliable delivery capabilities and attentive service, we have earned ongoing recognition and trust from our customers.

- Our Company

A Reliable Manufacturing Partner

Four Major Factories

We operate four large production bases for forging, slewing bearings, gearboxes, and castings, covering the complete industrial chain to meet diverse production needs.

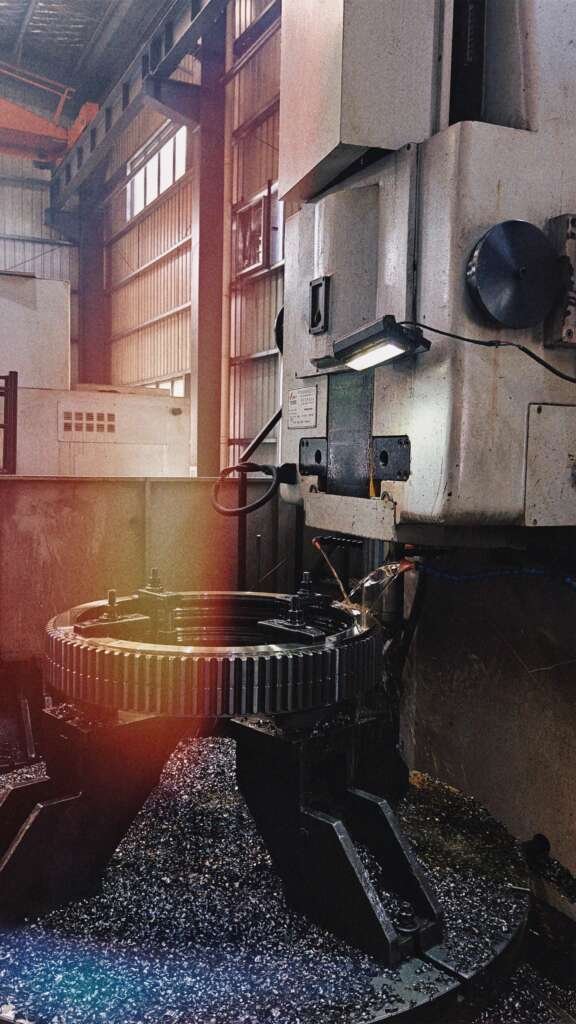

Advanced Equipment

Each factory is equipped with numerous advanced machines and production lines to ensure high efficiency and consistent product quality.

Experienced Workforce

Our workers possess extensive industry experience, enabling them to complete every product efficiently and accurately during production and assembly.

As a premier Slewing Bearing & Slewing Drive Manufacturer, Anhui Liyuan Transmission Technology Co., Ltd., founded in 2006, is a high-tech enterprise integrating R&D, design, manufacturing, and sales. We focus on providing core solutions for the construction machinery industry. Headquartered in Ma’anshan, Anhui Province, the company has built a complete industrial chain, covering all processes from raw material processing to finished product assembly.

Furthermore, as a leading Slewing Bearing & Slewing Drive Manufacturer, we operate four core production facilities: the Slewing Bearing Factory, Slewing Drive Factory, Forging Factory, and Casting Factory.

The company employs over 400 staff, including a dedicated R&D team of 65 senior and mid-level technical professionals, and holds more than 20 patents. Certified under the ISO9001 quality management system, our products are widely used in excavators, cranes, wind power equipment, and other applications.

+

Years of Industry Experience

+

Long-Term Partners

+

Factory Footprint

- Our Advantages

Six Key Advantages of Choosing Us

Our products are widely used in construction machinery, wind power equipment, port machinery, and industrial automation.

As a manufacturer of construction machinery components, we provide stable and reliable slewing support, precise transmission, and high-strength structural solutions for various types of equipment.

Product Applications

- Cooperation Progress

From Engineering to Delivery

Engineering Support

Our experienced engineering team provides design review and technical support,helping customers choose the right solution for their application.

Stable Manufacturing

With in-house forging, casting and machining,we ensure stable quality, efficient production and effective cost control.

On-time Delivery

Clear production planning and reliable logistics management help us deliver products on time to customers worldwide

- Q&A

Your Questions, Answered

How do I choose the right product for my equipment?

We offer a complete product catalog with a wide range of models for you to choose from. You can also share your working conditions with us, and our professional team will evaluate the load, environment, and functional requirements of your machine to select the most suitable product model.

Do you offer custom solutions for specific machinery applications?

Yes, we provide customized services. We can design tailor-made solutions based on your equipment needs and working conditions.

What is your lead time?

The lead time depends on the specific requirements, such as standard models or non-standard custom orders. Typically, it ranges from 15 to 45 days.

Can you provide product certifications or quality assurance?

Yes, we have an ISO9001 certification, and we provide a quality guarantee certificate for products upon delivery.

How can I get a quote for a custom or bulk order?

To receive a quote, please provide your drawings, technical parameters, and order quantity. Our technical department will calculate and provide a quote based on this information.

Get fastest Quotation

CLICK: Chat with us on our website

Or send a email with no hassle

The best is still to add our whatsapp