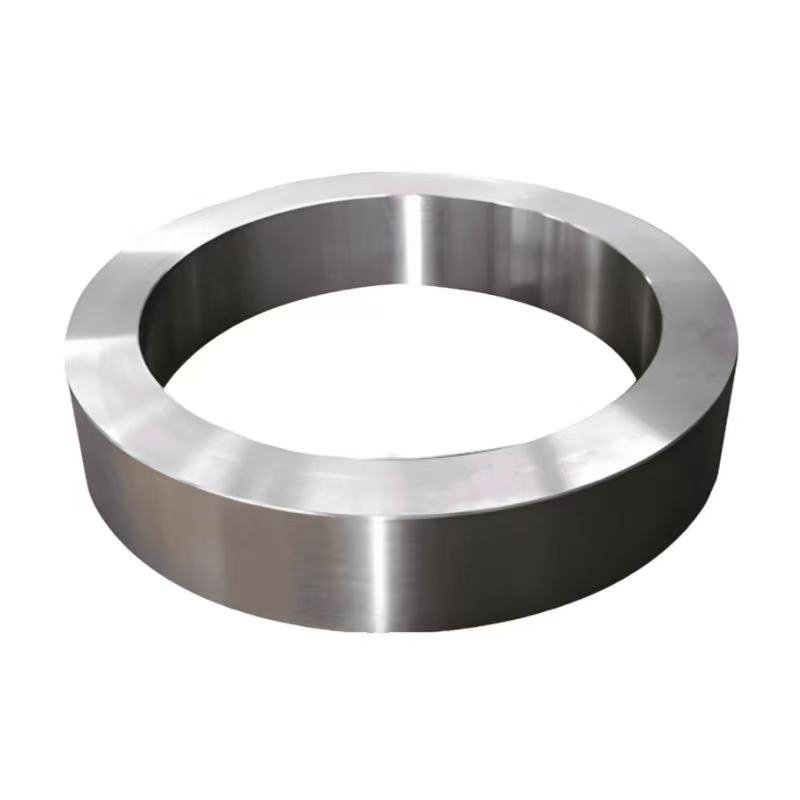

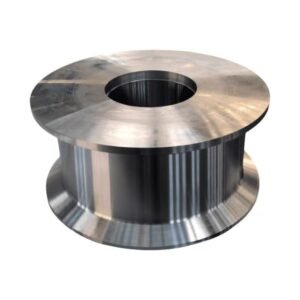

Ring Forging

| Material | Performance Parameters | Machining range (outer diameter) |

||||

| Tensile Strength (Rm/MPa) |

Yield Strength (RO.2/MPa) |

Elongation after Fracture (A/%) |

Reduction of Area (Z/%) |

Impact Energy (AKV/J@15°C) |

||

| 50Mn | 830 | 600 | 29 | 59 | 52 | 250mm-3000mm |

| S48C | 850 | 700 | 25 | 54 | 52 | |

| 42CrMo | 1000 | 900 | 21 | 60 | 95 | |

| 42CrMo4 | 1100 | 950 | 15 | 50 | 65 | |

| 35# | 550 | 350 | 25 | 50 | 61 | |

| 45# | 750 | 490 | 28 | 59 | 40 | |

| 16Mn | 550 | 345 | 21 | / | 40 | |

| Q345B | 550 | 300 | 20 | / | 40 | |

| 40CrNiMO | 1000 | 850 | 15 | 80 | 105 | |

Focused on the forging process and heat treatment of high-quality forgings, the performance of rings made from commonly used slewing bearing materials such as 50Mn, 42CrMo, and S48C far exceeds the national standard requirements for rolled products.

Reviews

There are no reviews yet.